Top Advantages of Using Robot AMR in Warehousing and Logistics

The rapid advancement of automation technology has brought significant transformation to warehousing and logistics operations. Among the most innovative solutions is the adoption of robot AMR (Autonomous Mobile Robots), which has revolutionized the way goods are transported and handled within facilities. These intelligent machines operate with remarkable efficiency and precision, allowing businesses to streamline their processes while reducing labor costs and minimizing human error.

The implementation of robot AMR can lead to enhanced productivity levels, enabling companies to keep pace with the ever-increasing demands of the e-commerce industry. By automating routine tasks such as picking, sorting, and transporting items, these robots free up human workers to focus on more complex and value-added activities. Furthermore, their ability to navigate autonomously within dynamic environments ensures that operations remain seamless and adaptable.

In addition to improving efficiency, robot AMR also plays a crucial role in enhancing safety within warehouses. By taking over potentially hazardous tasks, these robots help reduce workplace accidents and injuries, leading to a safer working environment. As businesses continue to explore ways to innovate and optimize their operations, the advantages of using robot AMR in warehousing and logistics become increasingly apparent, paving the way for a more automated and efficient future.

Understanding Autonomous Mobile Robots (AMRs) in Warehousing

Autonomous Mobile Robots (AMRs) have transformed the landscape of warehousing and logistics by providing

advanced solutions that enhance efficiency

and productivity. These robots are equipped with sophisticated sensors and AI algorithms, allowing them to

navigate complex environments and perform a variety of tasks autonomously. AMRs can transport goods, manage

inventory, and streamline workflows, reducing the reliance on manual labor

and minimizing human error.

In the context of warehousing, AMRs significantly improve operational efficiency. They can work around the

clock without fatigue, optimizing the movement of materials and reducing bottlenecks during peak times. By

automating repetitive and time-consuming tasks, AMRs enable

human workers to focus on more strategic activities, such as inventory management and customer service. The

integration of AMRs into logistics operations not only accelerates processes but also enhances overall safety

by reducing workplace accidents associated with traditional material handling methods. This innovative

technology represents a crucial step towards more intelligent and agile supply chain management.

Key Benefits of Implementing AMRs in Logistics Operations

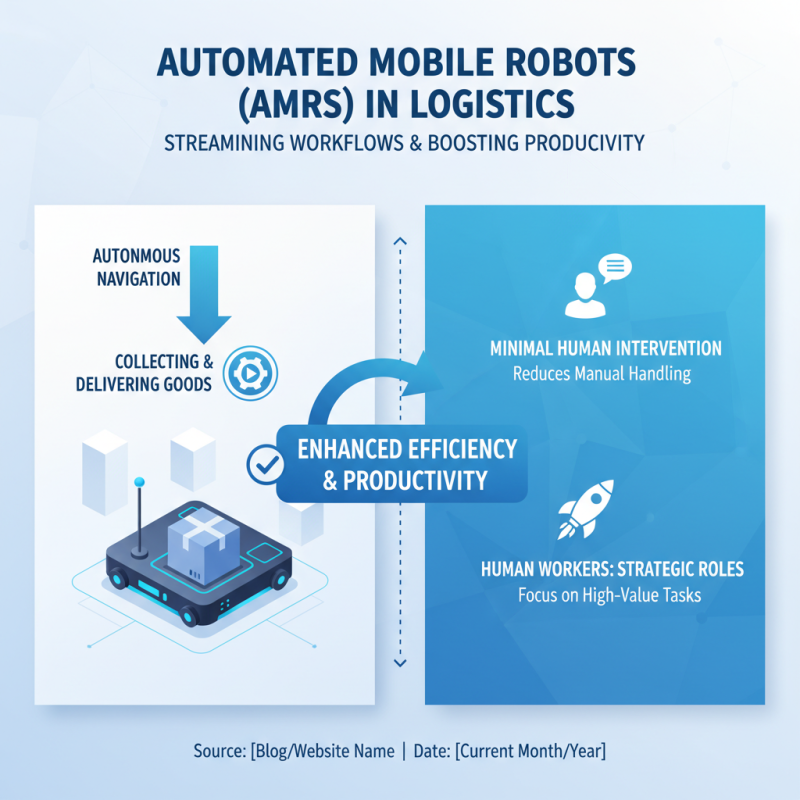

Automated Mobile Robots (AMRs) have become an essential component in modern logistics operations, providing a range of key benefits that enhance efficiency and productivity. One of the most significant advantages of implementing AMRs is their ability to streamline workflows. These robots can navigate autonomously through complex warehouse environments, collecting and delivering goods with minimal human intervention. This automation reduces the time spent on manual handling tasks, allowing human workers to focus on more strategic roles within the organization.

Another critical benefit of AMRs is their capacity for real-time data collection and monitoring. By integrating advanced sensors and software, these robots can gather vital information on inventory levels, order statuses, and operational efficiencies. This data not only aids in better decision-making but also facilitates the optimization of supply chain processes. As a result, businesses can adapt quickly to changing demands and improve overall service levels, ensuring timely deliveries and maximizing customer satisfaction.

Enhancing Efficiency Through Automation with AMRs

The adoption of Autonomous Mobile Robots (AMRs) in warehousing and logistics is revolutionizing the industry by significantly enhancing efficiency through automation.

AMRs streamline operations by automating repetitive tasks, such as picking, sorting, and transporting goods across the warehouse.

This automation not only speeds up these processes but also reduces the chances of human error, allowing for a more accurate and reliable workflow.

With AMRs efficiently handling the movement of inventory, employees can focus on higher-level tasks that require critical thinking and problem-solving skills, ultimately increasing overall productivity.

Furthermore, integrating AMRs into logistics systems can lead to better space utilization and improved inventory management.

As these robots are capable of maneuvering in tight spaces and navigating complex environments, they free up valuable floor space that can be repurposed for storage or other activities.

Additionally, AMRs continuously collect and analyze data during their operations, providing valuable insights into inventory levels and warehouse efficiency.

This data enables companies to make informed decisions about restocking, layout optimization, and operational enhancements, thereby driving continuous improvement within their logistics processes.

Improving Safety and Reducing Labor Costs with AMRs

The integration of Autonomous Mobile Robots (AMRs) in warehousing and logistics has significantly transformed operations, particularly in enhancing safety and reducing labor costs. AMRs are designed to navigate through aisles and deliver goods efficiently, minimizing the need for human labor in potentially hazardous environments. This automation not only protects employees from accidents but also decreases the incidence of workplace injuries, fostering a safer working atmosphere.

In addition to safety benefits, AMRs contribute to substantial cost savings. By automating repetitive tasks such as transporting products and inventory management, organizations can allocate their workforce to more skilled positions that require human oversight. This reallocation leads to improved productivity and decreases overall labor expenses. Moreover, as AMRs increase operational efficiency, businesses can fulfill orders faster, leading to higher customer satisfaction and potential revenue growth.

Tip: To maximize the benefits of AMRs in your operations, consider conducting a thorough analysis of your warehouse layout. This will help in optimizing robot paths and minimizing obstructions, ensuring smooth operations and enhanced safety.

Tip: Regular training and updates for your staff about AMR interactions can further improve safety and efficiency. Keeping your team informed will build confidence in working alongside these robots, fostering a culture of safety and teamwork.

Future Trends and Innovations in AMR Technology for Warehousing

As the warehousing and logistics industry evolves, the integration of Autonomous Mobile Robots (AMRs) is becoming increasingly vital. Future trends indicate that advancements in AMR technology will significantly enhance operational efficiency, reduce labor costs, and address labor shortages. According to a recent report by the International Federation of Robotics, the deployment of robotic systems in warehouses is expected to grow at a Compound Annual Growth Rate (CAGR) of 25% through 2025. This surge reflects a growing awareness of the efficiency gains attributed to AMR systems.

Emerging innovations in AMR technology include advanced perception capabilities enabled by Artificial Intelligence (AI) and Machine Learning (ML). These innovations allow robots to navigate and adapt to dynamic environments with greater precision, making them effective in diverse warehousing tasks—from picking and sorting to inventory management. A study by McKinsey suggests that implementing AMRs can improve productivity by up to 30%, allowing businesses to scale operations while maintaining cost-effectiveness.

Moreover, developments in collaborative robotics enable AMRs to work alongside human workers, creating a synergistic environment that maximizes productivity and safety in logistics operations.

As we look toward the future, the role of AMRs in warehousing is set to expand further with advancements like swarm robotics and enhanced battery technology, which will extend operational hours and efficiency. The continuous evolution of these technologies underscores the significant impact AMRs will have on shaping the future landscape of the logistics industry.

Related Posts

-

Exploring the Future of Work with Think Robotics Innovations

-

Maximizing Efficiency with Logistics Robotics A Comprehensive How to Guide

-

Challenges Faced by Industries Embracing Robotics and Automation

-

Robotics Automation: A Comparative Analysis of Leading Solutions for Global Buyers

-

10 Unmatched Robotics Innovations You Should Think About

-

How to Create a Robot: A Step-by-Step Guide to Build Your First Automation Machine