Why Agile Robotics is Transforming Automation in Various Industries?

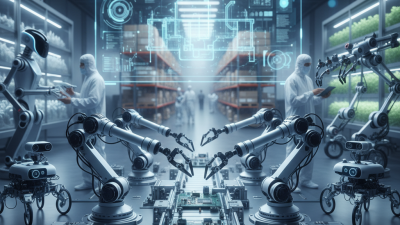

Agile robotics is reshaping the landscape of automation across multiple industries. By combining flexibility with efficiency, agile robotics allows companies to adapt quickly to changing demands. Instead of rigid, pre-programmed machines, these robots can learn and adjust in real time. This adaptability is crucial for businesses facing fluctuating market needs.

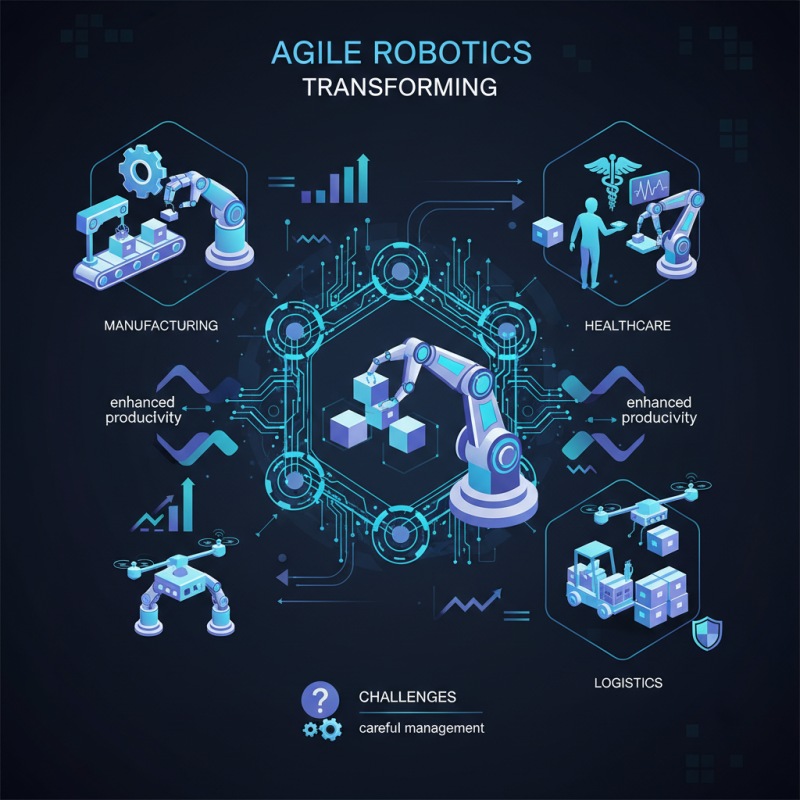

In industries like manufacturing, healthcare, and logistics, agile robotics enhances productivity. A factory might use agile robots to switch tasks on the fly. In hospitals, robots can assist with patient care, adjusting their actions based on real-time feedback. Such versatility leads to better resource allocation and improved outcomes.

However, the rapid integration of agile robotics also presents challenges. Organizations must rethink their workflows and training programs. Employees may feel threatened by these advanced systems, leading to resistance. Reflecting on these issues is essential for successful implementation. Embracing agile robotics can drive innovation, but it requires careful management and open conversations. The potential is vast, yet the journey demands thoughtful navigation.

The Definition and Principles of Agile Robotics in Automation

Agile robotics represents a significant shift in automation across various industries. This approach emphasizes flexibility and adaptability in robotic systems. Agile robots can quickly adjust to changing tasks, which is crucial in dynamic environments like warehouses and production lines. These robots utilize advanced sensors and AI, allowing them to learn and adapt as they work.

The principles of agile robotics focus on collaboration and versatility. Unlike traditional robots, which often require extensive reprogramming for new tasks, agile robots can switch between operations with ease. This capability not only improves efficiency but also reduces downtime. While the technology is impressive, there are still challenges to consider, such as the integration of these robots into existing workflows. Ensuring they communicate effectively with human workers can be a complex task.

Employees may feel apprehensive regarding job security as automation increases. It's essential to address these concerns and promote a culture of collaboration between humans and robots. Agile robotics can enhance productivity and create new roles. However, the balance between efficiency and workforce integration must be handled thoughtfully. This raises questions about the future of work and the evolving nature of automation.

Key Technologies Enabling Agile Robotics in Various Industries

Agile robotics is reshaping automation across multiple sectors. Key technologies drive this transformation, including advanced sensors, machine learning, and flexible control systems. According to a report by McKinsey, the market for robotics in manufacturing alone is expected to surpass $100 billion by 2025. It’s crucial for industries to harness this potential effectively.

Machine learning enables robots to adapt to new tasks. This adaptability is vital in environments where conditions change rapidly. Visual perception technologies allow robots to interpret their surroundings more accurately, improving operational efficiency. However, integrating these technologies can be complex and requires thoughtful planning. Companies must ensure their workforce is ready to interact with these systems.

**Tip:** Invest in workforce training. Address skill gaps early to avoid friction between employees and technology.

Flexible control systems further enhance performance. They allow robots to work alongside humans safely and efficiently. A report from PwC highlights that 45% of jobs in various sectors could be automated. Still, many leaders worry about job displacement. This concern underscores the need for balanced implementation strategies.

**Tip:** Collaborate with stakeholders. Engage with employees to find balanced integration solutions that benefit everyone.

Applications of Agile Robotics Across Different Sectors

Agile robotics is making waves in various sectors. In manufacturing, these robots adapt quickly to changes in production lines. They handle tasks like assembly, quality control, and packaging with remarkable speed. This flexibility allows manufacturers to respond to customer demands in real-time.

However, constant adjustments can lead to programming challenges, requiring skilled personnel to manage the systems effectively.

In logistics, agile robots enhance warehouse operations. They navigate spaces, transport goods, and optimize inventory management. The ability to work alongside human workers creates a dynamic environment. Yet, there are concerns about safety and the potential for accidents during busy hours. Training is needed to ensure seamless interactions between humans and robots.

Healthcare is another sector benefiting from agile robotics. Robots assist in surgeries, manage supplies, and improve patient care. Their precise movements minimize risks in sensitive procedures. Nonetheless, reliance on technology raises questions about patient privacy and data security. It’s crucial to establish effective protocols that address these concerns while harnessing the potential of agile robotics.

Benefits of Implementing Agile Robotics in Industrial Automation

Agile robotics is reshaping industrial automation across various sectors. One major benefit is flexibility. Robots can be quickly reconfigured for different tasks. A study by McKinsey indicates that 50% of tasks in manufacturing can be automated using robotics. This allows companies to adapt swiftly to changing demands.

Cost reduction is another significant advantage. Businesses often see a return on investment within months. An analysis from Deloitte showed that firms implementing agile robotics can reduce labor costs by as much as 30%. However, it requires upfront investment and training. The transition can be challenging.

Moreover, enhancing productivity is crucial. Agile robots work faster and more accurately than humans. Research from PwC suggests that productivity could increase by up to 40% with agile robotics. Yet, companies must also address integration issues with existing systems. Balancing speed and quality is vital for success.

Why Agile Robotics is Transforming Automation in Various Industries? - Benefits of Implementing Agile Robotics in Industrial Automation

| Industry | Key Benefits | Implementation Challenges | Future Trends |

|---|---|---|---|

| Manufacturing | Increased efficiency, reduced labor costs, enhanced precision. | Integration with existing systems, workforce retraining. | Collaborative robots, smart factories. |

| Logistics | Improved inventory management, faster delivery times. | Space limitations, ensuring safety in working environments. | Autonomous delivery systems, AI integration. |

| Healthcare | Enhanced patient care, efficiency in medical processes. | Regulatory hurdles, high costs of development. | Telemedicine robots, personalized healthcare solutions. |

| Agriculture | Increased crop yields, reduced labor intensity. | Weather dependency, high initial investment. | Drone technology, precision farming. |

| Construction | Faster project completion, improved safety. | Lack of skilled labor, initial costs of automation. | Robotic bricklaying, 3D printing technology. |

Challenges and Future Trends of Agile Robotics in Automation

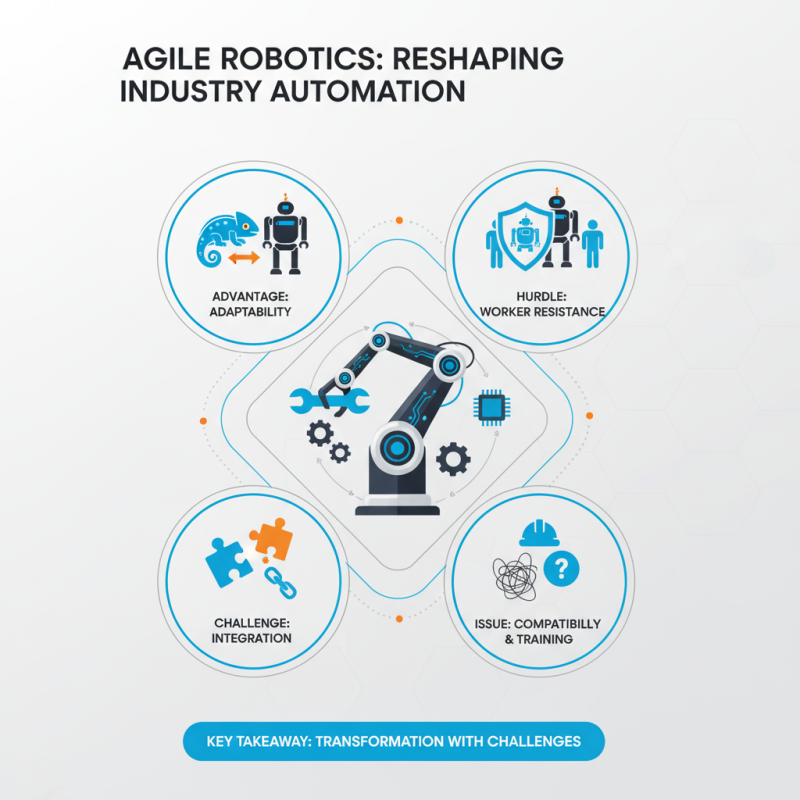

Agile robotics is reshaping automation across industries. This transformation brings significant challenges. The adaptability of agile robots is a key advantage. However, integrating them into existing systems is not straightforward. Companies often face issues with compatibility and training. Workers may feel threatened by these technologies, leading to resistance.

Future trends suggest that agile robotics will continue to advance. There is a growing interest in machine learning capabilities. However, developing truly intelligent robots is complex. Issues like safety and trust in these machines must be addressed. A deep understanding of human-robot interaction is crucial. Balancing efficiency and the human workforce is another concern.

The technology is promising, yet not without its flaws. Some robots struggle in complex environments. They may hesitate or malfunction when faced with unexpected obstacles. Continuous improvement is essential. Feedback loops from users can foster better designs. Reflection on these shortcomings can drive the next generation of agile robots. Embracing imperfection may be the key to advancing automation successfully.

Related Posts

-

10 Essential Tips for Effective Robotics Learning for Beginners

-

Top 10 Robotics Lab Innovations Shaping the Future of Technology

-

Why Robotics Lab is Essential for Future Innovations in Technology

-

Top 10 Innovative Think Robotics Solutions Transforming the Future of Automation

-

Top 10 Robotics Lab Innovations Transforming Technology and Education

-

2025 Top Trends in Agile Robotics: Transforming Industries with Innovation