2025 How to Choose the Best AMR Robot for Your Warehouse Operations

In the rapidly evolving landscape of warehouse operations, the adoption of Autonomous Mobile Robots (AMRs) is becoming increasingly vital for enhancing efficiency and productivity. According to a report by the research firm Gartner, the global AMR market is expected to reach $4.9 billion by 2025, driven by the growing demand for automation in logistics and manufacturing sectors. As warehouses aim to optimize their workflows and reduce labor costs, the selection of the right AMR robot becomes a crucial factor in ensuring operational success.

Industry experts, such as Dr. John Ferris, a leading authority in robotic automation, emphasize the importance of thorough evaluation in the AMR selection process. He states,

"Choosing the right AMR robot for your warehouse applications not only boosts operational throughput but also aligns with long-term strategic goals."As businesses grapple with increased order volumes and customer expectations, understanding the capabilities, compatibility, and scalability of various AMR solutions will be essential in crafting a competitive edge in the market.

Ultimately, as organizations prepare for the future of warehouse operations, making informed decisions about AMR technology can lead to significant cost savings and improved service delivery. With the right strategies in place, companies can leverage AMRs to navigate the challenges posed by a fast-paced industry while capitalizing on their vast potential.

Understanding AMR Robots: Types and Features for Warehouse Use

Autonomous Mobile Robots (AMRs) have become essential in streamlining warehouse operations. Understanding the different types of AMR robots available is crucial for effectively integrating them into your logistics processes. The primary categories include material handling robots, picking robots, and delivery robots. Material handling robots are designed for transporting goods within the warehouse, reducing the need for manual labor and improving efficiency. Picking robots, often equipped with advanced computer vision systems, can independently identify and retrieve inventory items, thus speeding up order fulfillment. Delivery robots, on the other hand, navigate through the facility to carry goods to designated locations, enhancing the speed of internal logistics.

When selecting an AMR for your warehouse, several features should be taken into account. Navigation technology is a key consideration; lasers, cameras, and LiDAR systems ensure the robots can map their environment and avoid obstacles effectively. Additionally, payload capacity plays a significant role; choosing a robot that can handle your typical load while maintaining efficiency is essential. Compatibility with existing warehouse management systems and ease of integration with current workflows can greatly affect the success of AMR implementation. By understanding these types and features, businesses can make informed decisions to optimize their warehouse operations with AMR technology.

Key Performance Indicators (KPIs) for AMR Robot Selection in Warehouses

When selecting an Autonomous Mobile Robot (AMR) for warehouse operations, understanding the Key Performance Indicators (KPIs) is essential to ensure that the chosen robot meets logistical demands and enhances efficiency. First, it's crucial to evaluate the robot's navigation accuracy. An AMR with high precision in navigating through aisles and avoiding obstacles can significantly reduce operational downtime and increase throughput. This is particularly vital in high-density warehouse environments where space is limited, and the pathway intricacies can be challenging.

Another important KPI to consider is the robot's load capacity and speed. Choosing an AMR that can efficiently handle the average weight of your products while maintaining optimal speed can lead to substantial improvements in order fulfillment times. Furthermore, analyzing the robot's battery life and recharge times will help determine its operational endurance during peak hours. By focusing on these KPIs, warehouse managers can make informed decisions that align with their specific operational goals, leading to enhanced productivity and cost-effectiveness.

2025 Key Performance Indicators (KPIs) for AMR Robot Selection in Warehouses

Evaluating AMR Robot Compatibility with Existing Warehouse Systems

When selecting the best Autonomous Mobile Robot (AMR) for warehouse operations, evaluating its compatibility with existing warehouse systems is crucial. This involves assessing how well the AMR can integrate with current software, conveyor systems, and inventory management tools. A seamless interface is essential for maximizing efficiency and minimizing disruptions in logistical processes.

Recent advancements in robotics highlight the importance of robust compatibility standards, as seen in the emergence of humanoid robots with multiple international certifications. Such developments suggest that AMRs must not only demonstrate operational effectiveness but also meet stringent regulatory criteria to ensure safe and efficient integration into diverse environments. Therefore, conducting thorough compatibility assessments before implementation can significantly enhance warehouse productivity and reduce operational downtimes.

Cost-Benefit Analysis of Implementing AMR Robots in Warehousing

Implementing Autonomous Mobile Robots (AMR) in warehouse operations can be a transformative decision, but it requires a thorough cost-benefit analysis. The initial investment in AMR technology can be significant, including the purchase of robots, necessary infrastructure modifications, and ongoing maintenance costs. Organizations need to evaluate not only these upfront costs but also factors such as training for personnel and integration with existing systems. A clear understanding of these expenses is essential to assess the financial viability of adopting AMRs.

On the benefit side, AMRs can dramatically increase operational efficiency and productivity. By automating routine tasks such as transporting goods and managing inventory, warehouses can reduce labor costs and minimize human errors. Moreover, AMRs enable more effective space utilization and can operate 24/7, thus maximizing throughput. This increase in efficiency can lead to higher order fulfillment rates and improved service levels, resulting in customer satisfaction. Ultimately, the decision to implement AMRs should stem from a detailed analysis that weighs both the direct and indirect financial implications against the operational advantages they bring to warehouse management.

2025 How to Choose the Best AMR Robot for Your Warehouse Operations

| Robot Model | Initial Cost ($) | Annual Maintenance Cost ($) | Throughput (Units/Hour) | Labor Cost Savings (%) | Payback Period (Years) |

|---|---|---|---|---|---|

| Model A | 50,000 | 5,000 | 150 | 30% | 2.5 |

| Model B | 70,000 | 7,000 | 200 | 40% | 3.0 |

| Model C | 60,000 | 6,000 | 180 | 35% | 2.8 |

| Model D | 80,000 | 8,000 | 220 | 50% | 3.5 |

Future Trends in AMR Robotics and Their Impact on Warehouse Efficiency

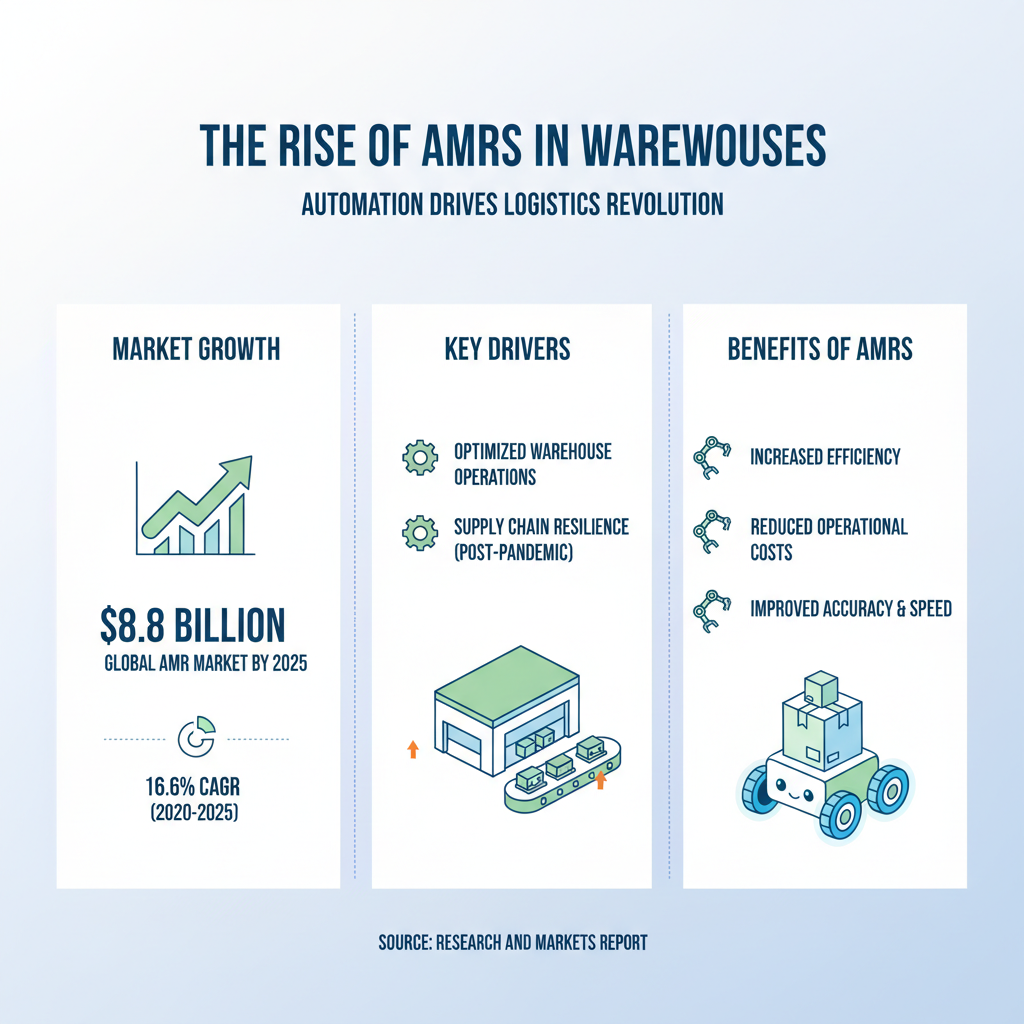

As warehouses increasingly embrace automation, autonomous mobile robots (AMRs) are at the forefront of revolutionizing logistics and operational efficiency. According to a report by the Research and Markets, the global AMR market is expected to reach $8.8 billion by 2025, with a compounded annual growth rate (CAGR) of 16.6% from 2020. This surge is driven by the growing demand for optimized warehouse operations, particularly in a post-pandemic landscape where supply chain resilience is paramount.

Future trends indicate a shift towards more intelligent and versatile AMRs that can seamlessly integrate with existing systems through advanced AI and machine learning capabilities. Data from McKinsey highlights that implementing AMRs can enhance warehouse productivity by up to 30%, while also reducing operational costs. As functionalities expand—such as improved navigation and enhanced safety features—the ability to adapt to various warehouse layouts will be crucial in maximizing efficiency. Moreover, the integration of AMRs with IoT technologies allows for real-time data sharing, ultimately leading to smarter decision-making and streamlined processes, positioning AMR robotics as a key component in future warehouse management strategies.

Related Posts

-

How to Maximize Efficiency with AMR Robots: Insights from the 2023 Logistics Automation Report

-

2025 Top Autonomous Robots Revolutionizing Industries and Daily Life

-

What is Robotics Learning and How It Transforms Education for Future Innovators

-

Unlocking the Future: An Ultimate Guide to Choosing the Right Autonomous Robot for Your Business

-

Exploring the Future of AMR Robots in Smart Warehousing and Supply Chain Optimization

-

Revolutionizing Supply Chain: Exploring AMRs at the 138th Canton Fair 2025 in China