How to Enhance Efficiency in Manufacturing by Rethinking Robotics Integration

The manufacturing industry is undergoing a significant transformation as companies strive to enhance efficiency and competitiveness in an increasingly complex market. According to a report by the International Federation of Robotics, global industrial robot sales reached a record high of over 422,000 units in 2021, which represents a 27% increase compared to the previous year. This surge underscores the growing recognition of robots as vital assets in streamlining operations.

However, to truly capitalize on the potential of robotics, it is essential for manufacturers to rethink robot integration beyond mere deployment. By strategically aligning robotic solutions with specific operational goals, organizations can achieve not only improved productivity but also enhanced adaptability in their production processes. Embracing this mindset will enable manufacturers to navigate challenges posed by labor shortages and supply chain disruptions, ultimately leading to more resilient and efficient manufacturing systems.

Strategies for Assessing Current Manufacturing Processes and Identifying Automation Opportunities

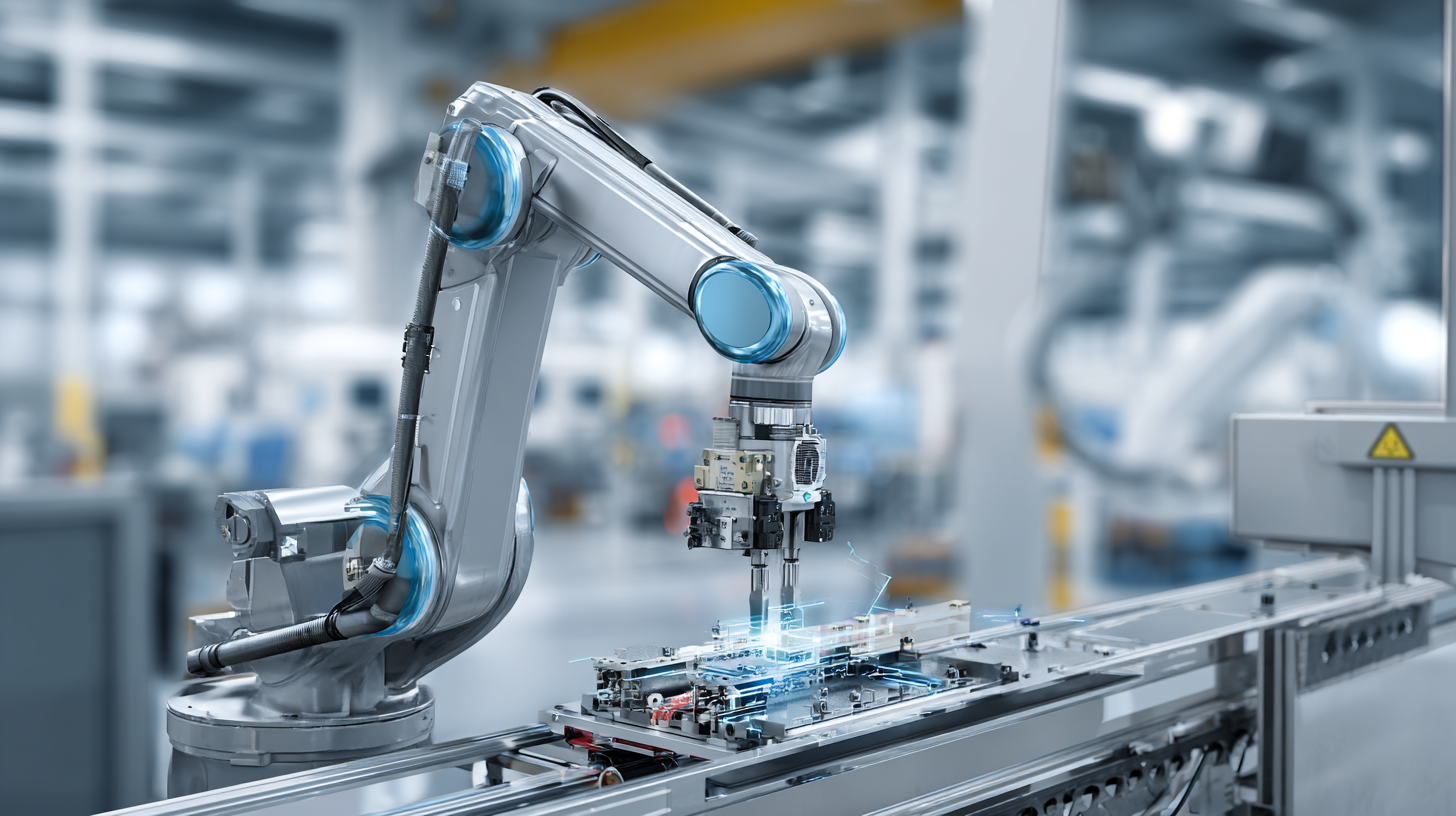

Assessing current manufacturing processes is crucial in identifying areas where robotics integration can enhance efficiency. Start by conducting a thorough evaluation of existing workflows, focusing on bottlenecks, repetitive tasks, and areas with high error rates. Collect quantitative data on production times and resource usage to establish baseline metrics. This analysis will help pinpoint processes that could benefit from automation, allowing for targeted implementation of robotics where they can provide the most value.

After identifying potential automation opportunities, consider the specific capabilities of different robotic systems. Evaluate the tasks that align with the strengths of robotics, such as precision handling, heavy lifting, or speed in repetitive tasks. Additionally, engage with employees across various departments to gather insights on pain points that may not be immediately apparent through data analysis alone. This collaborative approach ensures that the selected robotic solutions not only streamline operations but also complement the workforce, ultimately leading to a more efficient manufacturing environment.

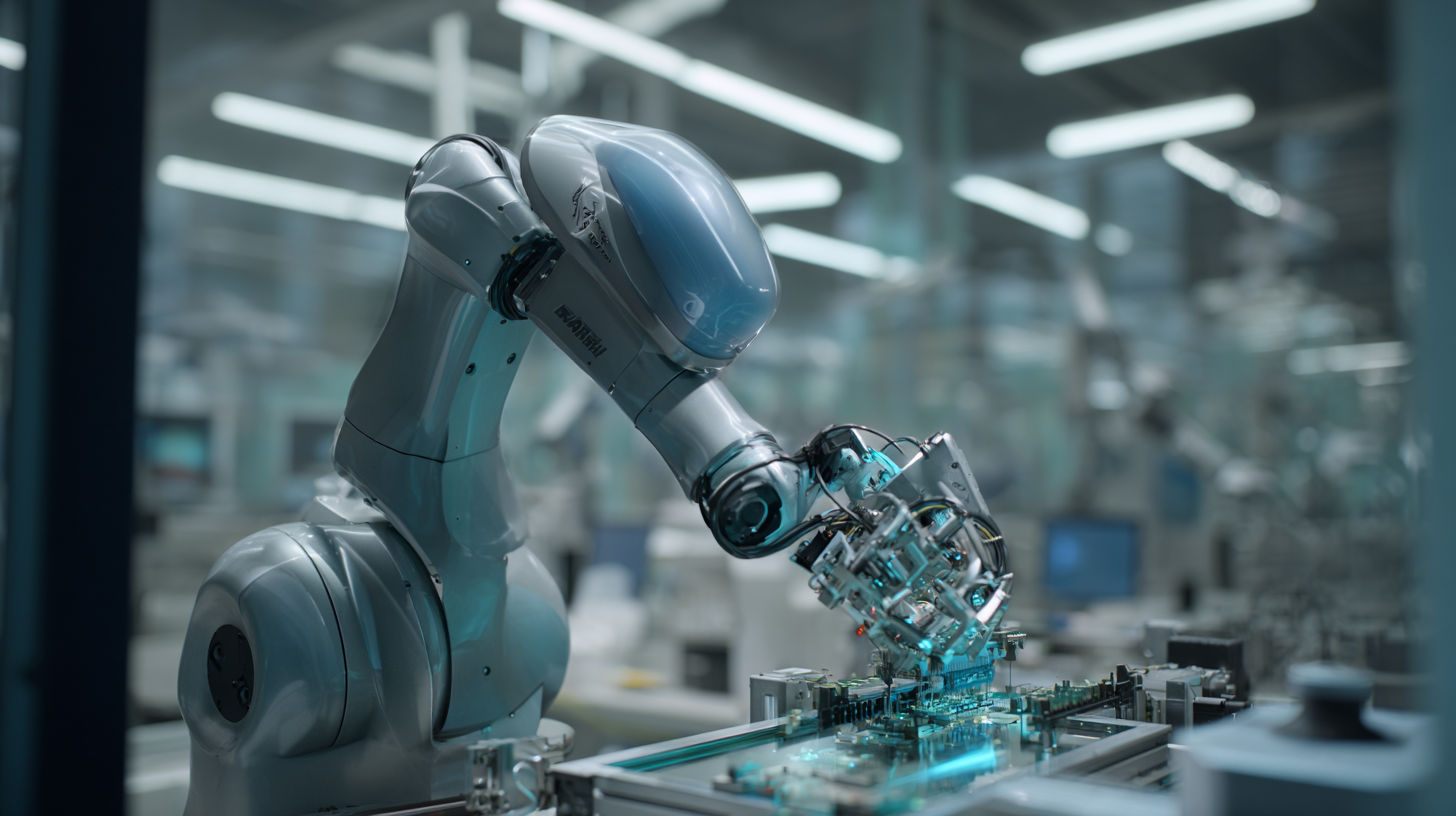

Key Robotics Technologies Driving Productivity Improvements in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of robotics technologies plays a pivotal role in driving productivity improvements. Recent industry reports indicate that companies leveraging advanced robotics can boost productivity by up to 30%, significantly reducing operational costs. Key technologies such as Collaborative Robots (Cobots), Artificial Intelligence (AI) applications, and Internet of Things (IoT) connectivity are transforming traditional manufacturing processes into highly efficient systems.

To enhance efficiency, manufacturers should consider adopting Cobots, which work alongside human operators to streamline tasks and minimize repetitive strain. According to a survey by the International Federation of Robotics, the use of Cobots is projected to grow by 30% annually, demonstrating their potential to improve workflow and safety on the factory floor.

**Tips:**

1. Assess your current operations to identify tasks that can be automated with robotics, ensuring a seamless integration with your existing workforce.

2. Invest in AI-driven analytics tools to monitor performance and optimize processes in real-time, increasing overall productivity.

3. Explore IoT solutions to create a connected manufacturing environment, enabling better communication between machines and enhancing decision-making capabilities.

Integrating Robotics with Workforce: Balancing Automation and Human Skills for Maximum Efficiency

The integration of robotics in manufacturing presents the unique opportunity to enhance operational efficiency while simultaneously preserving the invaluable contributions of human skills. As industries pivot towards automation, the focus must be on how to harmonize robotic capabilities with the expertise of the workforce. This balance can lead to a more resilient production process, where workers can take on roles that require creativity, problem-solving, and critical thinking—areas where humans excel over machines.

Moreover, fostering a collaborative environment where human workers and robots complement each other can unlock new levels of productivity. For instance, robots can handle repetitive, high-throughput tasks, freeing up human employees to engage in quality control and continuous improvement initiatives. By equipping the workforce with training on how to work alongside robotic systems, businesses can maximize efficiency and create a more adaptable workforce. In this way, the synergy between automation and human talent not only drives productivity but also enhances job satisfaction and retention among employees.

How to Enhance Efficiency in Manufacturing by Rethinking Robotics Integration

| Aspect | Description | Effect on Efficiency (%) | Comments |

|---|---|---|---|

| Robotic Automation | Implementation of robotic arms for assembly lines | 30 | Increases speed and precision in production. |

| Collaborative Robots | Using robots that work alongside human workers | 25 | Enhances flexibility and worker satisfaction. |

| Skill Development | Training programs for workers to handle advanced machinery | 20 | Boosts morale and operational competence. |

| Data Integration | Utilizing IoT for real-time data tracking on the floor | 35 | Improves decision-making and predictive maintenance. |

| Quality Control | Automating inspection processes with vision systems | 40 | Reduces defects and enhances product quality. |

Measuring the Impact of Robotics Automation on Manufacturing Productivity: Key Performance Indicators

In contemporary manufacturing, the integration of robotics automation presents a crucial opportunity to enhance productivity. To effectively measure the impact of this technology, organizations must identify and utilize key performance indicators (KPIs) that accurately reflect operational efficiency. Metrics such as cycle time reduction, overall equipment effectiveness (OEE), and defect rates serve as vital benchmarks for evaluating the performance of robotic systems. By continuously monitoring these KPIs, manufacturers can gain insights into areas of improvement and ascertain the return on investment from automation initiatives.

Furthermore, employee productivity and job satisfaction can also be influenced by the successful implementation of robotics. KPIs such as labor utilization rates and employee engagement scores can provide a comprehensive view of how robotics integration is reshaping the workforce dynamics. As robots take on repetitive and labor-intensive tasks, human workers can focus on higher-level functions, ultimately driving innovation and value creation within the organization. By analyzing these indicators, manufacturers not only measure the immediate effects of robotics but also position themselves for sustained growth in an increasingly competitive landscape.

Case Studies: Successful Robotics Integration in Manufacturing and Their Efficiency Gains

In recent years, successful robotics integration in manufacturing has transformed operational efficiency across various sectors, with the automotive industry being a prime example. The global automotive robotics market is projected to reach a value of $9.92 billion in 2024, with expectations to grow to $11.21 billion by 2025 and further to $26.76 billion by 2032. This remarkable growth underscores the critical role that robotics plays in enhancing productivity and driving innovation within the manufacturing landscape.

The concept of Industry 4.0 encompasses this shift towards smarter manufacturing, where digital transformation enables real-time decision-making and boosts flexibility and agility in production processes. By integrating advanced robotics and artificial intelligence, manufacturers can streamline operations, reduce waste, and improve product quality. Case studies illustrate that companies implementing these technologies have realized significant efficiency gains, showcasing how strategic integration and innovation are reshaping the future of manufacturing. This trend illustrates the necessity of rethinking robotics integration to stay competitive and respond to the evolving demands of the industry.

Related Posts

-

How to Enhance Your Business Efficiency with Think Robotics Solutions

-

10 Unmatched Robotics Innovations You Should Think About

-

Unlocking the Future: An Ultimate Guide to Choosing the Right Autonomous Robot for Your Business

-

Robotics Automation: A Comparative Analysis of Leading Solutions for Global Buyers

-

Ultimate Guide to Mastering Agile Robotics for Business Success

-

Challenges Faced by Industries Embracing Robotics and Automation