Exploring the Future of Warehouse Robotics at the 138th China Import and Export Fair in 2025

The rapid evolution of warehouse robotics is set to transform the logistics landscape, especially as we approach the 138th China Import and Export Fair in 2025. According to a recent report by ResearchAndMarkets, the global warehouse robotics market is projected to reach $27.9 billion by 2026, growing at a CAGR of 10.2% from 2021 to 2026. This surge in demand is driven by the need for efficiency, accuracy, and cost reduction in supply chain operations. As businesses increasingly adopt automated solutions, innovations in artificial intelligence and machine learning will enhance the capabilities of warehouse robotics, enabling them to handle more complex tasks and integrate seamlessly into existing workflows. The upcoming trade fair represents a pivotal opportunity for industry leaders and emerging startups alike to showcase their advancements in warehouse robotics, setting the stage for discussions on the future of logistics automation and the role of technology in meeting the demands of a rapidly changing market.

Innovations in Warehouse Robotics Showcased at the 2025 China Import and Export Fair

The 138th China Import and Export Fair in 2025 is set to be a pivotal event for the warehouse robotics industry, showcasing cutting-edge innovations that aim to revolutionize logistics and supply chain management. According to a report by ResearchAndMarkets, the global warehouse robotics market is expected to grow by 18.4% annually, reaching approximately $30 billion by 2026. This rapid growth underscores the urgent need for businesses to integrate automated solutions for efficiency and productivity.

At the fair, participants can expect to see advancements such as autonomous mobile robots (AMRs) that navigate through complex warehouse environments, enhancing order fulfillment processes. Furthermore, technologies like AI-driven inventory management systems and collaborative robots (cobots) will enable seamless interaction between humans and machines, drastically reducing operational costs. Insights from the latest industry surveys suggest that companies employing warehouse robotics experience a reduction in labor costs by up to 25%, highlighting the tangible benefits of these technological innovations.

Tips for businesses considering the adoption of warehouse robotics include:

- Conduct a thorough analysis of existing workflows to identify specific areas for automation.

- Stay informed about the latest technological advancements and partner with leading suppliers for integration support.

Key Trends Shaping the Future of Automation in Logistics

The adoption of robotics in warehouse operations is rapidly increasing, significantly advancing the logistics market. As companies strive for efficiency and cost-effectiveness, modern robotics are increasingly capable of managing the diverse and complex operations within the warehouse ecosystem. This evolution is powered by advancements in artificial intelligence, which enable robots to perform tasks with greater precision and adaptability.

The relevance of AI in robotics was notably underscored by Turing's predictions in the 1950s, laying the philosophical groundwork for future developments in intelligent machines. The integration of neural networks, championed by pioneers in the 1980s and the early 21st century, has further enhanced the capabilities of robotic systems. As the logistics industry navigates the changes brought by the COVID-19 pandemic, the push towards automation has accelerated, prompting businesses to rethink their operational models. This transformation positions logistics robots as central figures in redefining traditional practices and embracing a more automated future.

Impact of Robotics on Supply Chain Efficiency and Cost Reduction

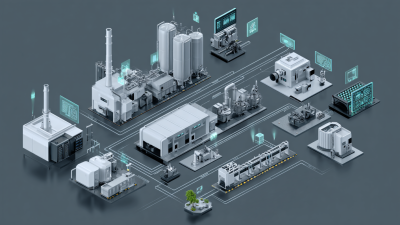

The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing the transformative impact of robotics on supply chain efficiency and cost reduction. As industries continue to evolve, the integration of advanced robotics technology presents unprecedented opportunities to streamline warehouse operations. Automated robotic systems can significantly reduce the time taken for inventory management, order fulfillment, and shipping processes, ultimately enhancing the responsiveness of supply chains to market demands.

Moreover, the adoption of robotics in warehouses leads to substantial cost savings. With automated systems handling repetitive tasks, businesses can minimize labor costs while reducing the likelihood of human errors. This not only accelerates operational workflows but also improves overall productivity. By investing in cutting-edge robotics, companies can achieve better resource allocation and optimize their supply chains, positioning themselves competitively in an increasingly dynamic marketplace. The fair highlights these advancements, demonstrating how robotics is reshaping the landscape of logistics and warehouse management.

Collaboration Between Technology Providers and Warehouse Operators

At the 138th China Import and Export Fair in 2025, the focus will be on the crucial collaboration between technology providers and warehouse operators. The integration of digital twins and AI has emerged as a powerful tool in optimizing supply chains. By creating AI-powered digital twins of warehouses, companies can significantly enhance operational efficiency and design flexibility. This innovative approach allows for real-time simulations that can inform better decision-making, streamline processes, and ultimately reduce costs.

Moreover, strategic partnerships are reshaping the landscape of warehouse automation. Collaborations between leading tech companies and warehouse operators enable the development of advanced solutions that effectively address industry challenges. As seen in recent initiatives, such partnerships harness technologies that bolster efficiency and visibility in operations. By fostering an environment of collaboration, stakeholders in the logistics sector can navigate the complexities of modern supply chains and drive forward the evolution of warehouse robotics, setting the stage for a more connected and efficient future in logistics.

Future Challenges and Opportunities for Robotics in Warehousing

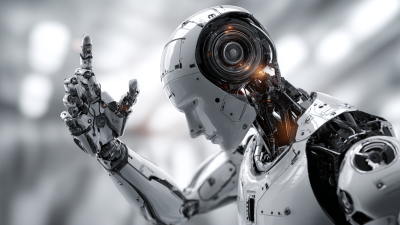

The landscape of warehouse robotics is poised for significant transformation as showcased at the 138th China Import and Export Fair in 2025. The event highlighted the future challenges and opportunities that will shape the integration of robotics in warehousing. One of the primary challenges identified is the need for seamless human-robot collaboration. As robots become more sophisticated, establishing effective workflows where human operators and machines work in tandem will be crucial. This requires not only advanced technology but also training programs that equip workers with the necessary skills to manage and interact with robotic systems.

On the opportunity side, the adoption of artificial intelligence and machine learning in warehouse robotics is revolutionizing operational efficiency. These technologies enable robots to make real-time decisions, optimize inventory management, and reduce downtime through predictive maintenance. As companies look to enhance their logistics operations, investing in robotics solutions presents a way to achieve increased productivity and reduction in operational costs. The ongoing advancements in battery technology and navigation systems further open the door for deploying robots in diverse environments, thereby driving innovation in the warehousing sector moving forward.

Related Posts

-

How to Create a Robot: A Step-by-Step Guide to Build Your First Automation Machine

-

How to Leverage Think Robotics for Enhanced Industrial Efficiency

-

10 Unmatched Robotics Innovations You Should Think About

-

Unlocking the Future: An Ultimate Guide to Choosing the Right Autonomous Robot for Your Business

-

How to Enhance Warehouse Efficiency with AMR Robots

-

The Future of Robotics Automation Transforming Industries with Data Driven Innovations