How to Create a Robot: A Step-by-Step Guide to Build Your First Automation Machine

In today's rapidly advancing technological landscape, the ability to create robot automation machines has become an increasingly accessible endeavor for hobbyists and engineers alike. This guide is designed to walk you through the essential steps needed to turn your robotic ideas into reality.

Whether you're a beginner or someone with prior experience in electronics and programming, understanding the core concepts involved in robot creation is crucial. From selecting the right components to coding the software that drives your automation machine, each step is vital in the journey of creating a functional robot.

As you embark on this exciting project, you will not only gain valuable skills but also experience the satisfaction of seeing your robot come to life. Prepare to unleash your creativity and technical prowess in this comprehensive, step-by-step guide tailored for anyone eager to create robot technology.

Understanding the Basics of Robotics: Components and Types of Automation Machines

In the realm of robotics, understanding the fundamental components and types of automation machines is crucial for any aspiring creator. Robotics generally encompasses various elements, such as sensors, actuators, and controllers. According to the International Federation of Robotics (IFR), the global market for industrial robots alone is projected to reach $75 billion by 2025, underlining the importance of grasping these basics for anyone looking to enter the field.

When it comes to types of automation machines, we see a spectrum ranging from simple mechanical devices to sophisticated robotic systems capable of complex tasks. Common automation machines include pick-and-place robots, autonomous mobile robots, and collaborative robots (cobots), designed to work alongside humans. A 2021 report from McKinsey indicates that by 2030, up to 375 million workers may need to switch occupations due to automation, highlighting the transformative impact of robotic systems in various industries.

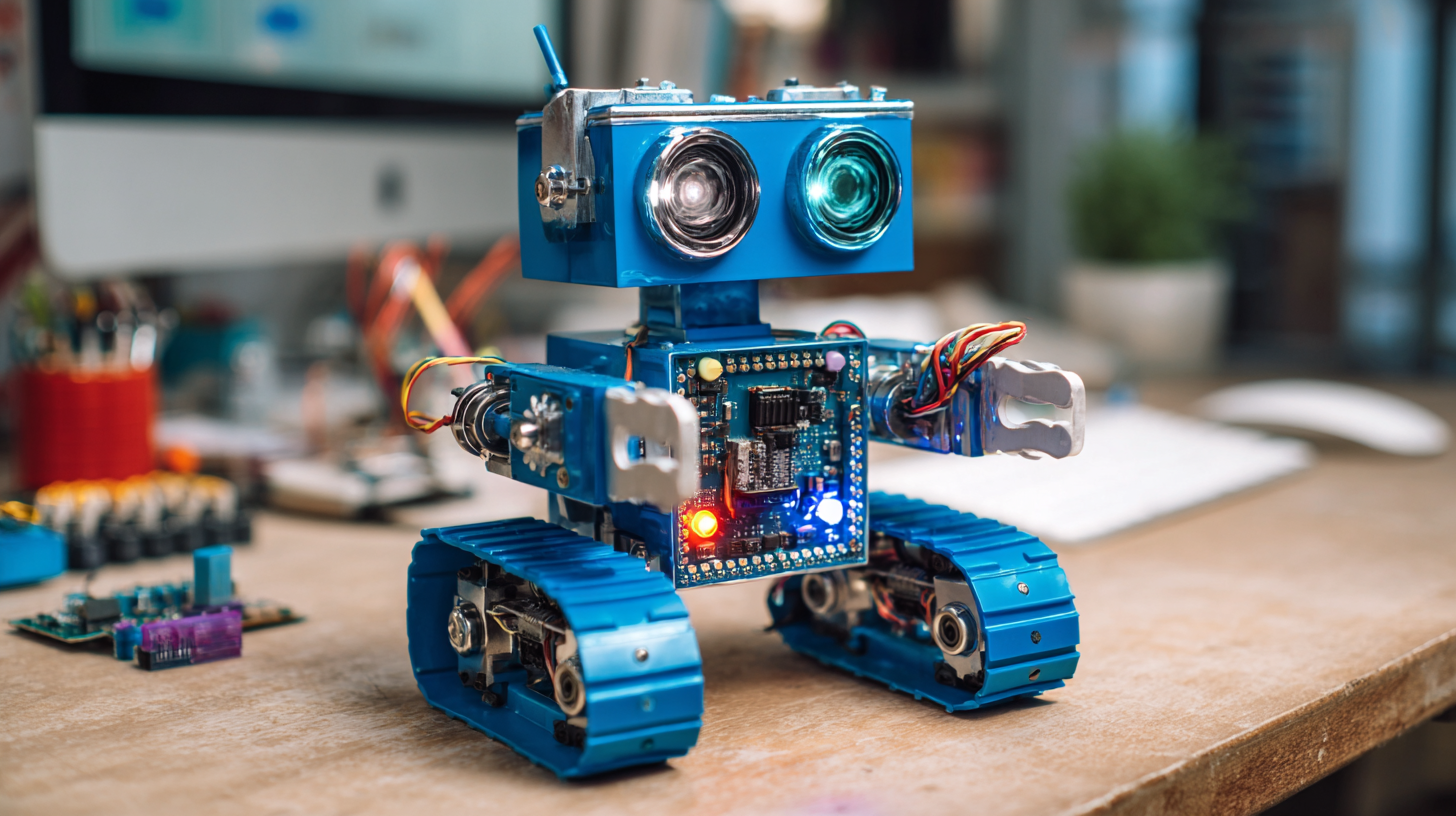

**Tips**: Start small by creating basic robotic projects that incorporate sensors and simple programming. Experimenting with platforms like Arduino or Raspberry Pi can dramatically enhance your understanding of robotics. Additionally, utilizing online forums and communities can provide valuable insights and troubleshooting assistance as you embark on your robotics journey.

How to Create a Robot: A Step-by-Step Guide to Build Your First Automation Machine

| Component | Description | Type |

|---|---|---|

| Microcontroller | The brain of the robot, controls operations and tasks. | Control Unit |

| Sensors | Devices that detect changes in the environment, such as light or distance. | Input |

| Actuators | Mechanisms that produce motion by converting energy into movement. | Output |

| Chassis | The frame that holds all components of the robot together. | Structure |

| Power Supply | Provides the necessary energy for all electronic components. | Energy Source |

| Code and Software | Programming that instructs the robot on how to perform tasks. | Control Logic |

Key Robotics Technologies: Sensors, Actuators, and Controllers in Modern Robots

In the world of robotics, the integration of key technologies such as sensors, actuators, and controllers is essential for creating efficient automation machines. Sensors serve as the “senses” of robots, allowing them to perceive their environment. According to a report by the International Federation of Robotics, the demand for sensor technology in the robotics industry is projected to grow by over 20% annually through 2025. This growth underscores the significance of incorporating accurate sensors for tasks ranging from object detection to environmental monitoring.

Actuators are another vital component, responsible for motion and control. They convert electrical energy into mechanical motion, enabling robots to perform complex tasks. The global market for actuators is expected to reach $60 billion by 2026, driven by advancements in robotics applications across various sectors, including manufacturing and healthcare. Choosing the right type of actuator—whether it's pneumatic, hydraulic, or electric—can significantly impact the robot's performance.

Tip: When selecting sensors, consider factors like sensitivity, range, and response time, as these attributes directly influence the robot’s ability to function effectively in its intended environment.

Controllers, the brain of the robot, process information from sensors and dictate the actions taken by actuators. Investing in high-quality controllers is essential for achieving precise movement and decision-making. Reports indicate that the robotics controllers market is set to expand significantly, highlighting the increasing need for robust control systems in intricate robotic applications.

Tip: Ensure the controller you choose supports the programming languages and development environments you are familiar with, facilitating a smoother development process.

The Importance of Programming in Robotics: Languages and Platforms for Beginners

Programming is a fundamental skill in robotics, especially for beginners looking to create their first automation machines. Various programming languages offer different features and capabilities suitable for robotics projects. Python, for instance, has gained tremendous popularity in the field due to its simple syntax and extensive libraries, making it ideal for tasks related to machine learning and artificial intelligence. Many creators prefer Python as it allows them to rapidly prototype robotic functions and integrate advanced algorithms seamlessly.

In addition, newer programming languages are emerging that cater specifically to niche applications within robotics. For instance, the recent introduction of the Chinese programming language "Mulan" has sparked a discussion about innovation and originality in software development. Yet, its comparisons with Python have raised eyebrows, emphasizing the importance of robust programming foundations.

As aspiring roboticists navigate through programming languages and platforms, they play a pivotal role in shaping the future of robotics, fostering creativity and technical skills necessary to build sophisticated automation systems.

Safety and Compliance in Robotic Automation: Regulations and Standards You Must Know

When embarking on creating a robotic automation system, understanding safety and compliance is paramount. Regulations and standards in the robotics industry ensure not only the safety of the operators but also the reliability of the machines. According to a report by the International Organization for Standardization (ISO), adherence to safety standards can reduce workplace accidents by up to 40%. Key regulations such as ISO 10218 and ISO/TS 15066 define the safety requirements for industrial robots, including risk assessment procedures and collaborative robot (cobot) interactions. It is essential to familiarize yourself with these standards to ensure that your automation project meets legal requirements and operates smoothly.

When embarking on creating a robotic automation system, understanding safety and compliance is paramount. Regulations and standards in the robotics industry ensure not only the safety of the operators but also the reliability of the machines. According to a report by the International Organization for Standardization (ISO), adherence to safety standards can reduce workplace accidents by up to 40%. Key regulations such as ISO 10218 and ISO/TS 15066 define the safety requirements for industrial robots, including risk assessment procedures and collaborative robot (cobot) interactions. It is essential to familiarize yourself with these standards to ensure that your automation project meets legal requirements and operates smoothly.

Tips: Before starting your automation project, conduct an extensive risk assessment. This process should include identifying potential hazards and implementing safety measures. Additionally, consider integrating safety-rated hardware and software, such as emergency stop systems and light curtains, to enhance operator protection.

Moreover, compliance with the Occupational Safety and Health Administration (OSHA) guidelines in the U.S. is crucial. OSHA emphasizes that all robotic installations must not only comply with the manufacturer's specifications but also with general industry safety regulations. Consistent training and updates for your team regarding these standards are vital as the robotics landscape continues to evolve, with a projected market growth reaching $210 billion by 2026 according to Statista. This growth amplifies the importance of rigorous safety practices in robotic automation.

Future Trends in Robotics: Market Growth and Applications across Various Industries

As industries continue to evolve, the demand for automation and robotics is surging, presenting numerous opportunities for growth. Future trends indicate that sectors such as manufacturing, healthcare, and logistics will increasingly embrace advanced robotic systems. These innovations not only enhance operational efficiency but also provide solutions to labor shortages and improve workplace safety. With the integration of artificial intelligence, robots are becoming smarter, enabling them to perform complex tasks with greater precision.

The market for robotics is projected to expand significantly over the coming years. According to industry forecasts, exponential growth is expected in collaborative robots or cobots, which work alongside humans, transforming traditional work environments. Additionally, sectors like agriculture are utilizing robotics for tasks such as planting and harvesting, leading to increases in productivity. Furthermore, the rise of service robots in areas like customer service and home automation is also shaping consumer expectations and behaviors, allowing people to benefit from personalized and efficient service experiences.

Related Posts

-

Challenges Faced by Industries Embracing Robotics and Automation

-

Robotics Automation: A Comparative Analysis of Leading Solutions for Global Buyers

-

Maximizing Efficiency with Logistics Robotics A Comprehensive How to Guide

-

The Future of Robotics Automation Transforming Industries with Data Driven Innovations

-

Ultimate Guide to Mastering Agile Robotics for Business Success

-

5 Best Innovations in Robotics Automation Transforming Industries