2025 How to Implement Agile Robotics for Enhanced Automation Efficiency

In today's rapidly advancing technological landscape, the integration of agile robotics into automation processes is becoming increasingly crucial for organizations aiming to enhance operational efficiency. Agile robotics refers to the design and implementation of robotic systems that are adaptable, flexible, and capable of responding quickly to changing environments and tasks. As industries strive for greater productivity and streamlined operations, the deployment of these innovative robotic solutions offers a transformative approach to automation.

The importance of agile robotics stems from its ability to foster collaboration between human workers and machines while improving overall workflow. By utilizing advanced algorithms and machine learning techniques, agile robots can be trained to perform a variety of tasks with minimal downtime. This adaptability not only promotes efficiency but also allows businesses to remain competitive in an ever-evolving market. As we explore the methodologies for implementing agile robotics effectively, it becomes evident that this technology will play a pivotal role in shaping the future of automation across diverse sectors.

As we look towards 2025, organizations must prioritize the integration of agile robotics into their operational frameworks to fully leverage the benefits of this cutting-edge technology. By embracing agile methodologies, companies can pave the way for improved automation efficiency, ultimately leading to enhanced productivity and sustainable growth. The following sections will delve into practical strategies and considerations for successfully implementing agile robotics in various industrial contexts.

Understanding Agile Robotics and Its Importance in Automation

Agile robotics merges flexibility and responsiveness, principles that are increasingly vital in the world of automation. Agile robots, designed to swiftly adapt to changing tasks and environments, stand out as technological solutions that can significantly enhance operational efficiency. According to a report by the International Federation of Robotics (IFR), the global market for robotic systems is projected to grow at a compound annual growth rate of 26% from 2021 to 2024. This rapid expansion underscores the importance of integrating agile robotics into various industries, providing businesses with a competitive edge in a landscape that demands rapid innovation and adaptability.

The importance of agile robotics in automation extends beyond merely fulfilling repetitive tasks; it fosters a synergistic relationship between human workers and machines. A study by McKinsey found that by 2030, up to 375 million workers may need to change occupational categories due to advancements in automation. Agile robots can relieve human workers from mundane tasks, allowing them to focus on strategic and creative roles that drive business success. Industries adopting agile robotic solutions are witnessing improved production rates, reduced downtime, and a greater ability to meet fluctuating customer demands. Emphasizing agility in robotics is not just about efficiency—it is a fundamental shift towards a more productive and sustainably automated future.

2025 Agile Robotics Automation Efficiency

This chart illustrates the projected increase in automation efficiency due to the implementation of Agile Robotics from 2021 to 2025. As companies adopt these technologies, a significant improvement in efficiency is anticipated.

Key Principles of Agile Methodology in Robotics Development

The integration of Agile methodologies in robotics development is proving to be a transformative approach towards enhancing automation efficiency. Agile principles, which emphasize iterative progress, collaboration, and adaptability, align well with the dynamic nature of robotics. According to a comprehensive report by the International Federation of Robotics, the global market for service robots is projected to exceed $47 billion by 2025, reflecting a growing demand for more efficient and responsive robotic solutions across various industries. This shift underscores the importance of agility in both development and deployment phases, enabling teams to adapt to rapid changes in technology and user requirements.

Key principles of Agile, such as user-centric design and continuous feedback loops, are particularly vital in robotics development. By utilizing Agile practices, teams can foster a collaborative environment where cross-functional stakeholders contribute to the product lifecycle. A study from McKinsey & Company indicates that organizations implementing Agile methodologies can achieve up to 30% faster project delivery times while significantly reducing development costs. This speed and efficiency are crucial in an industry where innovation cycles are quickly outpacing traditional development methods, making the case for an Agile approach indispensable for future robotics advancements.

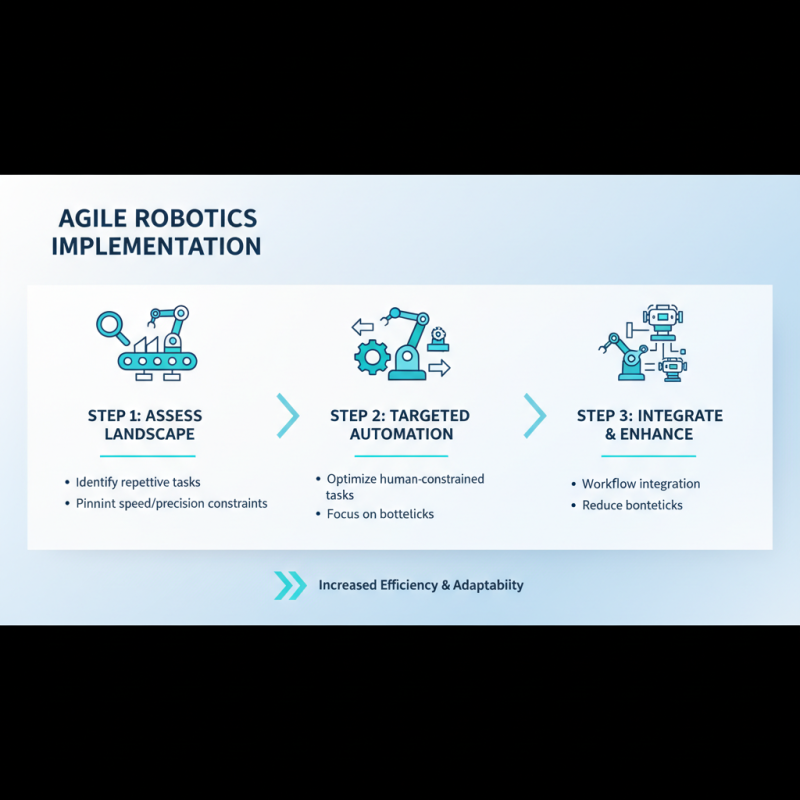

Steps to Implement Agile Robotics in Automation Processes

Implementing agile robotics in automation processes requires a systematic approach to ensure efficiency and adaptability. The first essential step is to assess the current automation landscape. This involves identifying repetitive tasks within production lines that can be optimized through robotic assistance. By looking for areas where human labor is constrained by speed or precision, organizations can target specific processes for automation. Once the tasks are identified, teams should analyze how agile robotics can be integrated to enhance workflow and reduce bottlenecks.

The next step is to design a pilot program that tests the integration of agile robotics in a controlled environment. This pilot should incorporate feedback mechanisms to monitor performance and adaptability. By utilizing simulation tools, companies can evaluate how robots can work alongside existing machinery and employees, ensuring seamless collaboration. After the pilot, it’s crucial to gather data on productivity improvements and cost savings, using this information to refine the implementation strategy. Continuous training and involvement of staff are also vital, as they will play an essential role in adapting to the new automated processes and ensuring that the technology aligns with operational goals.

Measuring Efficiency Improvements from Agile Robotics Integration

The integration of agile robotics into operational workflows can significantly enhance automation efficiency, but measuring the efficiency improvements can be challenging. To effectively gauge enhancements post-integration, organizations should establish relevant key performance indicators (KPIs) tailored to their specific processes. These KPIs could include metrics like cycle time reduction, error rate minimization, and overall productivity gains. By establishing a baseline of current performance before deploying agile robotics, companies can create a robust framework for comparison, providing clearer insight into the real impact of the technology.

Another crucial aspect of measuring efficiency improvements is the continuous monitoring of robotic performance. Employing real-time data analytics allows organizations to track the performance of agile robots as they adapt to various tasks and environments. By analyzing data over time, businesses can identify trends and changes in productivity, uncovering specific areas where the robots excel or require further optimization. This iterative approach not only highlights immediate gains but also prompts ongoing adjustments, ensuring that the integration of agile robotics leads to sustained performance enhancements and greater operational excellence.

Case Studies of Successful Agile Robotics Implementations

In the realm of automation, agile robotics has emerged as a transformative technology, fostering improved efficiency and adaptability in various industries. One notable case study is in the automotive manufacturing sector, where a leading company implemented a fleet of agile robots that communicate in real-time to manage assembly tasks. This integration allowed for a significant reduction in downtime, as robots could easily reassign themselves to different stations based on current workflow demands. The result was a more dynamic production line that responded instantly to variations in output requirements, leading to a 20% increase in overall productivity.

Another compelling example comes from the logistics industry, where a major warehouse utilized agile robots for inventory management. By adopting a modular robotic system, the facility could swiftly adjust its operations to accommodate seasonal peaks in demand. These robots utilized advanced machine learning algorithms to optimize their routes, ensuring faster picking and packing times. The implementation led to a decrease in order fulfillment times by approximately 30%, showcasing how agile robotics not only enhances operational efficiency but also significantly improves customer satisfaction through faster delivery times.

Related Posts

-

The Future of Robotics Automation Transforming Industries with Data Driven Innovations

-

Ultimate Guide to Mastering Agile Robotics for Business Success

-

Unlocking the Future: An Ultimate Guide to Choosing the Right Autonomous Robot for Your Business

-

How to Maximize Efficiency with AMR Robots in Your Business Operations

-

How to Leverage Think Robotics for Enhanced Industrial Efficiency

-

Rethinking Robots: How Innovative Technology is Shaping Our Future Workspaces