How to Leverage Think Robotics for Enhanced Industrial Efficiency

In today's rapidly evolving industrial landscape, integrating advanced technologies has become paramount for enhancing operational efficiency. A recent report by McKinsey highlights that organizations leveraging automation and robotics can achieve productivity gains of up to 30%. This shift towards automated solutions underscores the necessity to "think robotics" as companies seek innovative ways to streamline processes, minimize costs, and improve output quality. Furthermore, according to the International Federation of Robotics, global robot installations are expected to reach 2.7 million units annually by 2025, signifying a robust demand for automation across various sectors. By adopting a strategic approach to think robotics, industries can not only remain competitive but also drive sustainable growth in an increasingly automated future.

Understanding Think Robotics: Key Features and Benefits for Industries

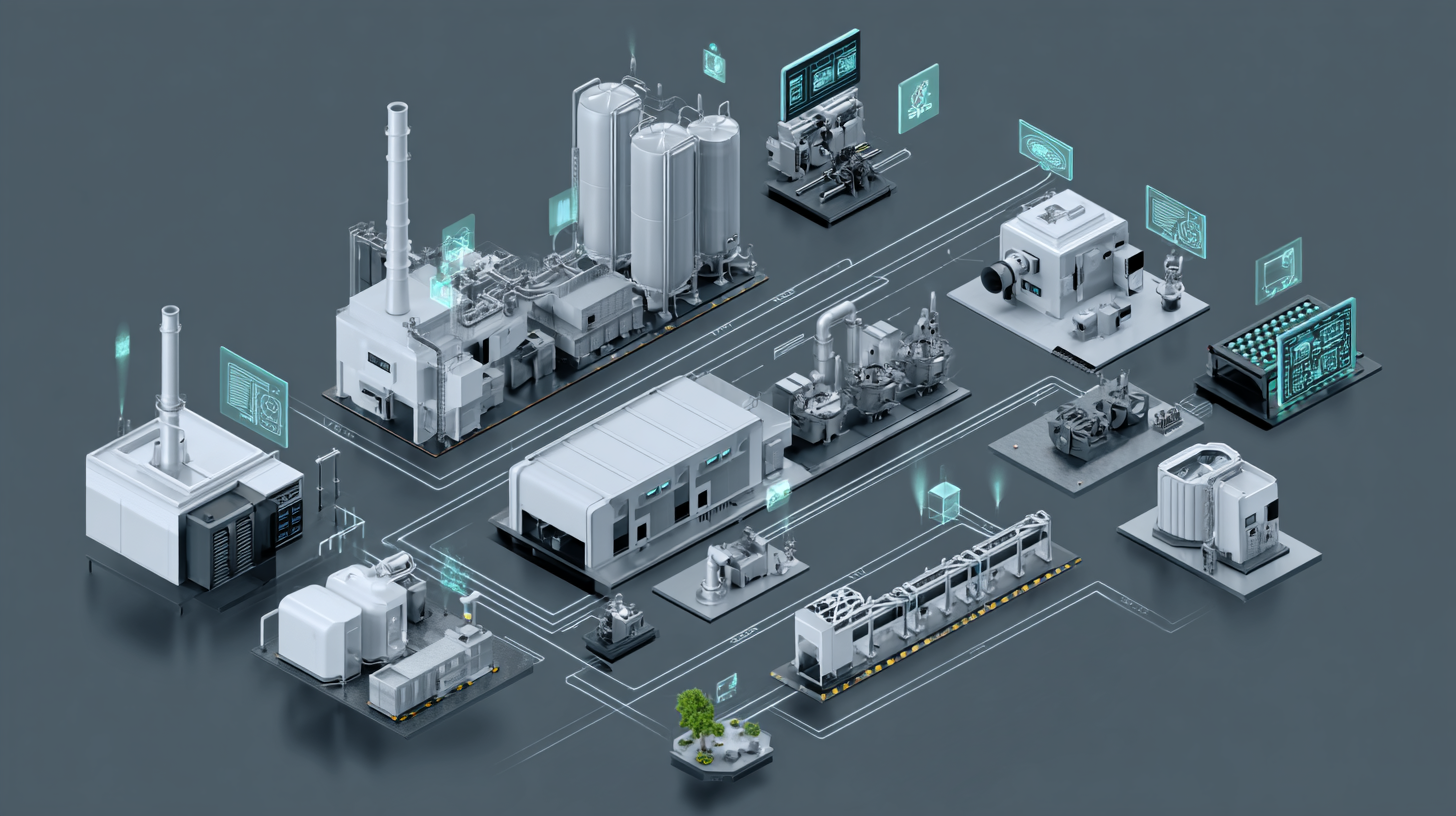

Think Robotics integrates advanced technologies to bolster industrial efficiency through a suite of innovative features tailored for various sectors. Central to its appeal is the integration of the Internet of Things (IoT), which enhances real-time data collection and analysis. This connectivity allows businesses to monitor machinery, optimize operations, and improve maintenance schedules, resulting in increased uptime and productivity. With IoT sensors embedded in robotic systems, industries can significantly reduce operational costs while enhancing precision in tasks ranging from assembly lines to logistics.

Moreover, the application of artificial intelligence (AI) within Think Robotics enables adaptive learning and decision-making processes. This synergy of robotics and AI is transforming traditional workflows, particularly in automotive manufacturing, where predictive maintenance and smart assembly processes redefine efficiency standards. The adoption of robotic process automation (RPA) is also emerging in sectors such as hospitality, where critical success factors include streamlined operations and enhanced guest experiences. By harnessing these key features, industries can unlock new levels of performance and responsiveness, positioning themselves competitively in a rapidly evolving marketplace.

How to Leverage Think Robotics for Enhanced Industrial Efficiency

| Key Features | Benefits for Industries | Application Areas | Impact on Efficiency |

|---|---|---|---|

| Automation Integration | Reduces labor costs | Manufacturing | Increases productivity by 30% |

| Real-time Data Processing | Improves decision-making speed | Logistics | Boosts operational efficiency |

| Adaptive Learning Algorithms | Enhances process optimization | Quality Control | Reduces defects by 25% |

| Scalability | Supports business growth | Supply Chain Management | Enhances flexibility in operations |

| Advanced Safety Features | Lowers accident rates | Construction | Promotes safer work environment |

Integrating Think Robotics into Existing Workflows for Maximum Impact

Integrating Think Robotics into existing workflows can significantly enhance industrial efficiency by streamlining processes and reducing operational bottlenecks. According to a report by McKinsey, the adoption of robotics in manufacturing could increase productivity by up to 30% while also minimizing production costs by as much as 20%. This powerful potential can be realized by seamlessly incorporating robotic solutions that complement human workers, allowing for more efficient task allocation and improved output.

By leveraging Think Robotics, companies can modernize their workflows through automation technologies that adapt to diverse operational environments. For instance, Boston Consulting Group highlights that early adopters of robotic process automation have witnessed a reduction in error rates by over 80%, illustrating the positive impact of integrating advanced robotics into routine tasks. Moreover, enhancing data visibility and real-time analytics through these robotic systems can empower businesses to make data-driven decisions, thereby catalyzing continuous improvement and agility within their operations. Integrating Think Robotics can provide the agility required to stay competitive in an ever-evolving market landscape.

Training Your Workforce to Utilize Think Robotics Effectively

Training your workforce to utilize Think Robotics effectively is essential for maximizing the benefits of this advanced technology. Workforce training not only empowers employees but also ensures smooth integration of robotic systems into existing workflows. Companies should focus on hands-on training sessions that familiarize workers with the operational intricacies of Think Robotics systems. This approach enhances confidence and allows employees to troubleshoot common issues independently.

- Interactive Workshops: Organize interactive workshops that include practical demonstrations. Engaging employees in real-world scenarios will help them understand the capabilities and limitations of the robots.

- Customized Training Programs: Develop tailored training programs that address the specific needs and competencies of various job roles within the organization. Customizing content ensures employees grasp concepts that are directly applicable to their tasks.

- Continuous Learning Culture: Foster a culture of continuous learning by providing ongoing training and resources. Encourage staff to stay updated on new features and best practices, ensuring they can adapt to evolving technology and maintain operational efficiency.

Measuring the ROI of Think Robotics Implementation in Operations

Implementing robotics within industrial operations requires a strategic approach to effectively measure the return on investment (ROI). Companies must first identify the critical elements that contribute to successful robotics integration. This includes assessing current operational challenges such as labor shortages, supply chain disruptions, and the pressures of economic constraints. Addressing these challenges with robotic solutions can not only enhance productivity but also streamline processes, ultimately leading to improved efficiency.

Moreover, businesses should focus on scaling their robotic initiatives beyond pilot projects. This involves leveraging advanced technologies like artificial intelligence and digital twins, which can provide invaluable insights into operational performance. By continually monitoring these technologies’ impact, companies can quantify the benefits of robotics and adjust their strategies accordingly. Workforce upskilling is equally important, ensuring that employees can effectively collaborate with robotics to maximize their potential in driving operational success. Through a comprehensive understanding of these factors, organizations can confidently measure and showcase the tangible ROI of their robotics investments.

Measuring the ROI of Think Robotics Implementation in Operations

This chart represents the ROI measured in percentage after the implementation of Think Robotics across various industrial sectors over a period of three years.

Case Studies: Successful Applications of Think Robotics in Various Sectors

The integration of Think Robotics into industrial workflows has demonstrated significant enhancements in operational efficiency across various sectors. For instance, in the automotive industry, a major manufacturer deployed Think Robotics for their assembly line processes, resulting in a 30% increase in production speed. The advanced robotic arms enabled precise and consistent handling of components, reducing human error and downtime. This case highlights the ability of Think Robotics to automate repetitive tasks while maintaining high-quality standards.

Similarly, in the food processing sector, a company utilized Think Robotics for packaging and sorting operations. By implementing automated solutions, they were able to increase their throughput by 20% and minimize waste during packaging. The robots were designed to adapt to different product sizes and shapes, showcasing flexibility that is crucial in a fast-paced industry. These successful applications underline the versatility of Think Robotics in driving efficiency and productivity, transforming traditional industrial practices into streamlined operations.

Related Posts

-

5 Best Innovations in Robotics Automation Transforming Industries

-

Ultimate Guide to Mastering Agile Robotics for Business Success

-

5 Best Innovations in Think Robotics for the Future of Automation

-

Unlocking the Future: An Ultimate Guide to Choosing the Right Autonomous Robot for Your Business

-

Maximizing Efficiency with Logistics Robotics A Comprehensive How to Guide

-

The Future of Robotics Automation Transforming Industries with Data Driven Innovations