Revolutionizing Supply Chain: Exploring AMRs at the 138th Canton Fair 2025 in China

As the global supply chain landscape undergoes a transformative shift, the integration of technology has become paramount in enhancing efficiency and reducing operational costs. The 138th Canton Fair in 2025 will spotlight the revolutionary role of robot AMRs (Autonomous Mobile Robots) in this domain. According to a recent report by Allied Market Research, the global market for AMRs is projected to reach $18.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 24.5% from 2019. This growth is driven by the increasing demand for automation across various sectors, including manufacturing, logistics, and e-commerce. The Canton Fair will serve as a pivotal platform for industry leaders to showcase cutting-edge innovations in robot AMRs, illustrating their capacity to streamline warehouse operations, enhance delivery systems, and ultimately reshape the supply chain industry. Attendees will have the opportunity to explore the latest advancements, offering insights into how these technologies can drive business efficiency and sustainability in a rapidly evolving marketplace.

AMRs: The Next Frontier in Supply Chain Transformation at Canton Fair 2025

At the 138th Canton Fair in 2025, the spotlight will be on Autonomous Mobile Robots (AMRs), marking a pivotal moment in supply chain transformation. As industries increasingly embrace automation and technological innovation, AMRs are emerging as a game-changer in logistics and supply chain management. These intelligent robots promise to enhance efficiency by streamlining the movement of goods within warehouses and production facilities. Their ability to operate autonomously, navigate complex environments, and seamlessly integrate with existing systems makes them an attractive solution for businesses looking to improve operational performance.

At the 138th Canton Fair in 2025, the spotlight will be on Autonomous Mobile Robots (AMRs), marking a pivotal moment in supply chain transformation. As industries increasingly embrace automation and technological innovation, AMRs are emerging as a game-changer in logistics and supply chain management. These intelligent robots promise to enhance efficiency by streamlining the movement of goods within warehouses and production facilities. Their ability to operate autonomously, navigate complex environments, and seamlessly integrate with existing systems makes them an attractive solution for businesses looking to improve operational performance.

The integration of AMRs in supply chains represents the next frontier of innovation, as they not only reduce labor costs but also minimize human error and improve accuracy in inventory management. By showcasing the latest advancements in AMR technology at the Canton Fair, exhibitors will provide insights into how businesses can leverage these robots to better meet growing consumer demands and adapt to market fluctuations. As the fair attracts industry leaders and innovators, discussions surrounding the future of AMRs and their role in redefining logistics will undoubtedly be at the forefront, setting the stage for the next wave of supply chain evolution.

Innovative Technologies Showcased: AMRs and Their Impact on Logistics

At the 138th Canton Fair in 2025, the spotlight will be on Autonomous Mobile Robots (AMRs) and their transformative potential in the logistics sector. These cutting-edge technologies are not only redefining traditional supply chain practices but also enabling businesses to enhance efficiency and reduce operational costs. By automating the movement of goods within warehouses and distribution centers, AMRs facilitate a seamless flow of products, ensuring that businesses can respond rapidly to market demands.

The innovative capabilities of AMRs, such as precise navigation and real-time data processing, allow for optimized inventory management and improved delivery timelines. As logistics companies increasingly adopt these systems, the impact on supply chain accuracy and consistency becomes evident. Moreover, AMRs contribute to a safer workplace by minimizing human error and reducing the likelihood of accidents in bustling environments. The integration of such technologies at events like the Canton Fair underscores a pivotal shift towards smarter, more resilient supply chains, showcasing not only the current advancements but also hinting at future developments that could further revolutionize the logistics landscape.

Real-World Applications of AMRs in Supply Chain Management

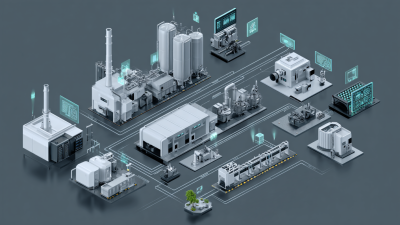

The 138th Canton Fair 2025 is set to spotlight the transformative role of Autonomous Mobile Robots (AMRs) in supply chain management. These cutting-edge machines are not just futuristic concepts; they are making significant strides in real-world applications, enhancing efficiency and accuracy in the logistics arena. By automating tasks such as inventory management, order fulfillment, and transportation within warehouses, AMRs minimize human error and accelerate operational processes. This integration leads to reduced operational costs and allows companies to focus their human resources on strategic, high-value tasks.

Moreover, the use of AMRs improves safety in supply chain environments. By taking over repetitive or hazardous tasks, these robots not only enhance productivity but also create a safer working environment for employees. Companies leveraging AMRs can also gain valuable data insights, optimizing their supply chain operations further. As the industry gathers at the Canton Fair, attendees will witness firsthand how these innovations are shaping the future of supply chain management, paving the way for smarter, more agile operations in a rapidly evolving market.

Case Studies: Successful Implementation of AMRs by Industry Leaders

At the 138th Canton Fair in 2025, the spotlight will shine on Autonomous Mobile Robots (AMRs) as transformative tools in supply chain management. Industry leaders have begun successfully implementing AMRs, showcasing their potential through various case studies. For instance, logistics giant DHL reported a 15% increase in operational efficiency after integrating AMRs into their warehousing processes, allowing for smoother and faster material handling. This aligns with industry forecasts, predicting that the AMR market will grow to $14 billion by 2026, driven by increased automation in logistics.

Another notable example comes from Amazon, which has deployed thousands of Kiva robots across its fulfillment centers. These AMRs have been reported to reduce the time for order fulfillment by up to 50%, significantly impacting the company's ability to meet consumer demand swiftly. A recent report by McKinsey suggests that companies leveraging robotics and automation can achieve supply chain cost reductions of up to 30% while enhancing accuracy and speed. As organizations continue to adopt these advanced technologies, the insights shared at the Canton Fair will provide invaluable lessons for others looking to innovate their supply chain operations.

Revolutionizing Supply Chain: AMRs Implementation Insights

This bar chart illustrates the annual implementation of Autonomous Mobile Robots (AMRs) from 2021 to 2025, highlighting a significant upward trend, indicative of the growing adoption of automation in supply chain processes.

Future Trends: The Role of Automation in Shaping Supply Chains Post-2025

As we look towards the future of supply chains beyond 2025, automation is poised to play an increasingly critical role in shaping operational efficiency and responsiveness.

According to a report by McKinsey, companies that implement automation technologies can reduce operational costs by up to 30%, significantly enhancing their competitive edge.

The 138th Canton Fair 2025 will showcase Advanced Mobile Robots (AMRs) as a key element in this transformation, allowing businesses to optimize workflows, reduce labor-intensive tasks, and minimize errors in warehouse management.

The integration of automation solutions is not just a trend but a necessity in the wake of ongoing global supply chain disruptions.

Research from the World Economic Forum predicts that by 2027, up to 25% of jobs in logistics could be automated, leading to improved efficiency and reshaping workforce dynamics.

The 138th Canton Fair will present innovative AMRs that can adapt to various environments and operate alongside human workers, demonstrating how businesses can leverage technology to enhance productivity while fostering a collaborative work atmosphere.

Embracing these technological advancements will be essential for companies aiming to remain agile and efficient in the evolving landscape of global trade.

Related Posts

-

How to Maximize Efficiency with AMR Robots: Insights from the 2023 Logistics Automation Report

-

10 Unmatched Robotics Innovations You Should Think About

-

Unlocking the Future: An Ultimate Guide to Choosing the Right Autonomous Robot for Your Business

-

How to Enhance Efficiency in Manufacturing by Rethinking Robotics Integration

-

5 Best Innovations in Think Robotics for the Future of Automation

-

How to Leverage Think Robotics for Enhanced Industrial Efficiency