Why Robotics Automation is the Future of Manufacturing and Workplaces

The advent of robotics automation marks a pivotal shift in the landscape of manufacturing and workplaces. As industries face increasing pressure to enhance efficiency, reduce costs, and meet ever-evolving customer demands, robotics automation offers a compelling solution. This technology leverages advanced algorithms and machine learning to perform tasks traditionally carried out by human workers, thereby optimizing productivity and precision. With the ability to operate continuously and adapt to various functions, robotics automation not only streamlines processes but also addresses labor shortages and enhances workplace safety.

Moreover, the integration of robotics automation into manufacturing is transforming job roles and the skill sets required in the workforce. As repetitive and dangerous tasks become automated, employees are freed to focus on more complex and creative responsibilities. This shift necessitates a new culture of continuous learning, wherein workers must adapt to emerging technologies and understand how to collaborate effectively with robots. Consequently, the future of manufacturing is not merely about machines replacing human labor; rather, it reflects a synergistic relationship where technology empowers the workforce to achieve greater innovation and excellence.

The Evolution of Robotics Automation in Manufacturing

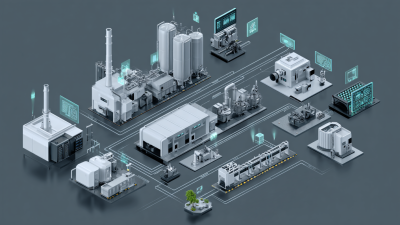

The evolution of robotics automation in manufacturing has transformed the landscape of industrial operations, facilitating a shift from traditional manual labor to highly efficient automated systems. Initially, manufacturing relied heavily on human workers for tasks that often required repetitive motion and significant physical labor. However, advancements in robotics technology have introduced systems capable of performing these tasks with precision and speed, significantly increasing output and minimizing the potential for human error.

Over the last few decades, robotics automation has integrated sophisticated algorithms, artificial intelligence, and machine learning, empowering machines to adapt to changing conditions and complex manufacturing processes. This evolution allows for greater flexibility on the production floor, where robots can now be programmed to handle varied tasks, from assembly to quality control. As industries continue to embrace these innovations, we witness enhancements in productivity and efficiency, which not only improve operational effectiveness but also enable companies to respond more swiftly to market demands. The continual development of robotics automation promises to redefine the future of manufacturing and workplaces, setting the stage for a more advanced and intelligent industry.

Why Robotics Automation is the Future of Manufacturing and Workplaces

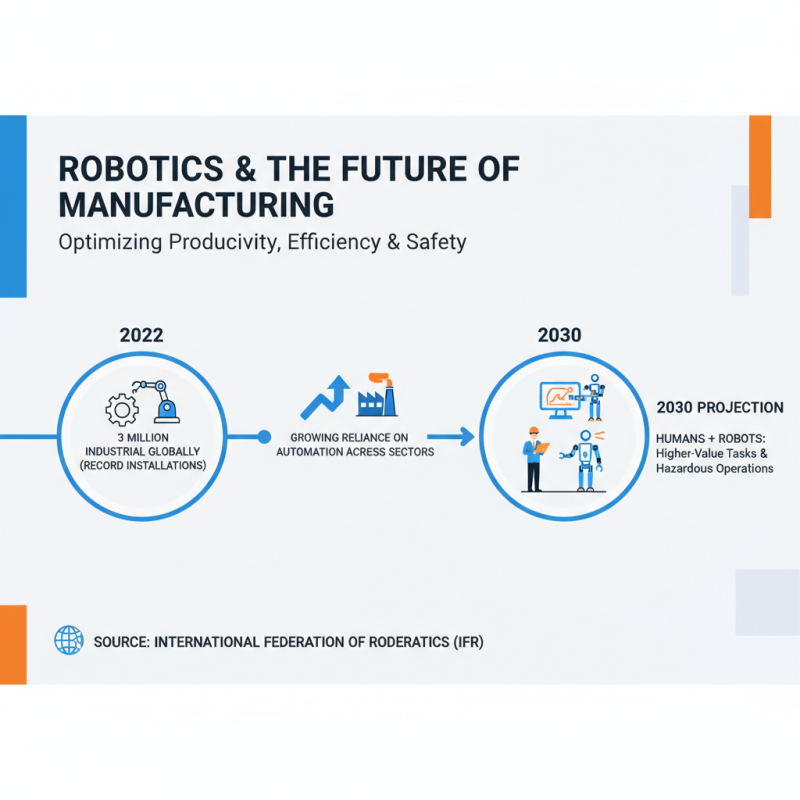

The chart above illustrates the increasing adoption rate of robotics automation in manufacturing from 2018 to 2023. This trend emphasizes the growing reliance on automation technology in modern workplaces, marking a significant shift towards more efficient and productive manufacturing processes.

Key Technologies Driving Robotics Automation in Workplaces

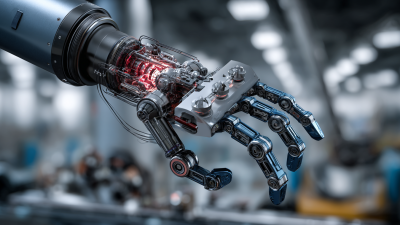

The landscape of manufacturing and workplaces is undergoing a seismic shift driven by robotics automation. A recent report from the International Federation of Robotics predicts that the global stock of operational industrial robots will reach 3 million units by 2025, underscoring the rapid adoption of automation technologies. Key technologies propelling this revolution include artificial intelligence (AI), machine learning, and the Internet of Things (IoT). AI facilitates more efficient and autonomous decision-making processes, enabling robots to adapt to varying tasks and environments with minimal human intervention. This transition not only enhances productivity but also creates safer work conditions by taking over hazardous jobs.

Moreover, autonomous mobile robots (AMRs) are reshaping logistics and material handling within warehouses and production facilities. According to a study by Transparency Market Research, the AMR market is anticipated to grow at a CAGR of over 18% from 2020 to 2027. This growth can be attributed to their ability to navigate complex environments while increasing operational efficiency. Integration of IoT with robotics enables real-time data collection and analysis, which allows businesses to optimize their workflows and minimize downtime. As these technologies continue to mature, the potential for innovative applications in various sectors will expand, setting the stage for a more streamlined and automated future in manufacturing and workplaces.

Benefits of Implementing Robotics Automation in Manufacturing

The implementation of robotics automation in manufacturing brings a multitude of benefits that can revolutionize production processes. Firstly, robotics automation significantly enhances efficiency and productivity. Unlike human workers, robots can operate continuously without the need for breaks, resulting in higher output levels. They also perform tasks with precision, reducing errors and waste, which contributes to more streamlined operations and improved quality control. This efficiency not only leads to cost savings but also allows companies to meet increasing consumer demands in a timely manner.

In addition to efficiency, robotics automation can also enhance workplace safety. Repetitive and hazardous tasks that pose risks to human workers can be delegated to robots, minimizing the chances of workplace accidents. By taking over dangerous jobs, robots contribute to a more secure working environment, ultimately benefiting employee health and morale. Moreover, the integration of robotics in manufacturing can lead to upskilling of the workforce as employees transition to roles that require more advanced technical expertise, fostering a culture of innovation and continuous improvement within organizations.

Why Robotics Automation is the Future of Manufacturing and Workplaces - Benefits of Implementing Robotics Automation in Manufacturing

| Dimension | Description | Benefits |

|---|---|---|

| Increased Efficiency | Robots can work continuously without breaks, increasing production rates. | Higher output, faster turnaround times, and reduced labor costs. |

| Improved Precision | Automation reduces human error and improves consistency. | Higher quality products and less waste in manufacturing processes. |

| Enhanced Safety | Robots can perform dangerous tasks, reducing risks to human workers. | Lower injury rates and improved workplace safety. |

| Cost Savings | While initial investment is high, long-term costs are reduced through automation. | Savings on labor and operational efficiency leading to greater profit margins. |

| Scalability | Robots can be scaled up or down depending on demand without extensive retraining. | Flexible production lines that can adapt to market needs swiftly. |

Challenges and Considerations in Adopting Robotics Systems

The rapid advancement of robotics automation is transforming the manufacturing and workplace landscapes, but adoption is not without its challenges and considerations. According to a report by the International Federation of Robotics (IFR), global sales of industrial robots are projected to reach 2.2 million units by 2025, marking a significant increase in automated processes across various sectors. However, companies must address several hurdles when integrating these technologies.

One primary challenge is the need for substantial initial investment. Implementing robotics systems can lead to high upfront costs, including purchasing, installation, and training. Research from Deloitte indicates that over 80% of manufacturing executives see the cost of technology as a major barrier to adopting automation. Furthermore, organizations must also consider workforce displacement concerns, as jobs traditionally held by humans may become obsolete, necessitating a focus on reskilling and upskilling initiatives to enable workers to transition into new roles in a more automated environment. Ultimately, the path to successful robotics integration involves careful planning and assessment of both financial implications and workforce dynamics.

Future Trends and Predictions for Robotics in the Workforce

The future of manufacturing and workplaces is undeniably intertwined with the advancement of robotics automation. According to a report by the International Federation of Robotics (IFR), by 2022, global robot installations surged to a record number, with an estimated 3 million industrial robots anticipated to be in use. This trend reflects a growing reliance on automation across multiple sectors, optimizing productivity and efficiency while addressing labor shortages. By 2030, it is projected that robotics will augment the capabilities of the workforce, enabling human workers to focus on higher-value tasks while robots handle repetitive and hazardous operations.

Furthermore, the World Economic Forum (WEF) predicts that by 2025, 85 million jobs may be displaced by the integration of technology, including robotics, yet the same report suggests that 97 million new roles could emerge, particularly in areas such as robotics maintenance, programming, and supervision. The shift towards automation is not just about job displacement but also about the evolution of the workplace. Companies are investing in collaborative robots (cobots) designed to work alongside humans, enhancing safety and efficiency. This collaborative approach is expected to dominate workplace design and structure, fostering an environment where technology and human skills are synergistically utilized, paving the way for a more innovative and productive future in manufacturing and beyond.

Related Posts

-

Exploring the Future: How Robotics and Automation Transform Everyday Life

-

5 Best Innovations in Robotics Automation Transforming Industries

-

Top 10 Innovative Think Robotics Solutions Transforming the Future of Automation

-

How to Leverage Think Robotics for Enhanced Industrial Efficiency

-

Challenges Faced by Industries Embracing Robotics and Automation

-

Ultimate Guide to Mastering Agile Robotics for Business Success